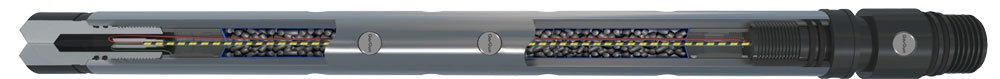

51mm GasGun® System

The GasGun is a solid-propellant well-stimulation device based on proprietary ballistic technology from the U.S. military. It incorporates the most advanced design on the market with the use of progressively burning propellants that have been proven by independent research to be many times more effective in creating fractures and increasing formation permeability.

The GasGun is a solid-propellant well-stimulation device based on proprietary ballistic technology from the U.S. military. It incorporates the most advanced design on the market with the use of progressively burning propellants that have been proven by independent research to be many times more effective in creating fractures and increasing formation permeability.

The patent pending 2” GasGun system uses a self-tailoring design which allows the tool to adjust to a wide range of fielding conditions. The carrier is engineered with recessed ports (rupture disks) that are machined to exacting tolerances. These ports help enable the propellant to deliver an optimal pressure profile to the reservoir. When the GasGun is fielded in deep-tight reservoirs, or in wells with little clearance between the carrier and casing/tubing, the gun will build up higher internal pressures resulting in a large percentage of the ports blowing out. This ensures carrier integrity and delivers pressures high enough to create multiple fractures in the reservoir. When the GasGun is fielded in shallower soft-rock reservoirs, or in wells with more clearance between the carrier and casing/tubing, a smaller percentage of the ports will blow out. It is not uncommon to have more than 50% of the ports remain intact after a GasGun stimulation. This differs greatly from conventional perforating guns which use shape charges to perforate casing. By design the propellant inside the GasGun will rupture as many ports as necessary to deliver all of the energy contained in the carrier to the reservoir.

– Engineered for thru-tubing and other slimhole applications.

– Reduce cost by eliminating the need to remove tubing prior to stimulation

– Creates multiple radial fractures into the formation up to 6 meters (20 feet) from the wellbore.

– Designed for 2.875” tubing/casing and larger.

– Wireline and tubing-conveyed systems available for both vertical and horizontal wells.

– Expendable high strength steel carrier

– Arming procedures comply with API RP-67.

– Patented design.

– Prepares well for hydraulic fracturing by breaking down formation first.

– Removes skin and cleans up the wellbore damaged by perforators, drilling fines, cement, paraffin, mud cake, etc.

– Improves effectiveness of acidizing by fracturing first with the GasGun.

– Minimal vertical fracture growth avoids problems often associated with hydraulic fracturing.

– Reduces injection pressure and improves flow rates in injection and waste disposal wells.

– Enhances production in naturally fractured reservoirs by intersecting more fractures.